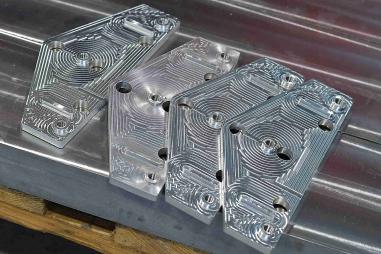

We have a long tradition of cnc machining.

CNC milling

- custom CNC milling

- cutting of threads on the milling machine

- drilling and neck flanges

- cnc flange manufacturing

- cnc machining centres with 3rd and 4th axis

We provide custom CNC milling for series production of metal parts and components for industry. At the same time, we also offer small batch and piece production of milled parts, which is provided by conventional milling within our company.

We offer CNC milling At the same time, we also provide small batch and piece production of milled parts, which is covered by conventional milling within our company.

CNC turning

- cnc production of inner threads

- thread cutting on the lathe

- drilling of the holes

- cnc flange manufacturing

The maximum turning diameter of our CNC lathes is 330 mm.

In the field of CNC metal turning, we specialize in the large/small scale production of parts for industry, as well as one-off production. Mostly manufactured parts are made of aluminum, stainless and structural steel as well as plastic.